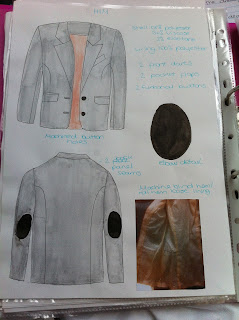

Design Package

For my design package i designed a range of jacket design ideas, this included technical information which i labelled on each jacket design front and back to show where things such as the pockets,darts and top stitch detail will go.

Final Design

Here is my final design that i decided to choose for creating my final jacket sample. My final design features added volume to the top of the sleeve, a stand up collar with top stitched detail, front and back shoulder/ waist darts. Along with two front patched pockets with top stitched detail on them.

My final jacket featured two front shoulder darts, two bust darts, two front patch pockets with a stand up collar. The back of the jacket features two back should darts and two lower back darts. Instead of making half a jacket i decided to make a full jacket to show that i am capable of making a full jacket with lining. By making a full jacket this has helped me to be more confident by pushing the boundaries showing what im capable of producing when i put my time and effort into it.

Front view

Back View

Two back shoulder darts

Front patch pocket with top stitch detail

Stand up collar close up

Sleeve with slightly added volume to the top of the sleeve

During this project i pushed the boundries by completing a full jacket to the best of my ability, taking in consideration all the tailoring skills i have learned. By learning new skills has made me aware of what it takes create a tailored jacket as well as the time and effort involved in making it. I feel confident in making a jacket by using the new skills i have learnt and adapting them into my third year collection.